HOLZHER CNC MACHINING CENTERS

HOLZHER CNC machines for solid wood and panels: CNC machining solutions to make you even more potent in competition:

The PRO-MASTER 70 series from HOLZ-HER makes it easier than ever to decide in favor of efficient CNC technology. The 70 series offers rational machining and a high level of flexibility especially for production of case parts. With 180 mm from the top of the suction cups, the 70 series from HOLZ-HER offers the maximum working height in its class.

The PRO-MASTER 70 series from HOLZ-HER makes it easier than ever to decide in favor of efficient CNC technology. The 70 series offers rational machining and a high level of flexibility especially for production of case parts. With 180 mm from the top of the suction cups, the 70 series from HOLZ-HER offers the maximum working height in its class.

This well-thought-through concept offers solutions for all applications – choose the right model for your application. State-of-the-art safety concepts give you the choice between patented 3-field foot mats, safety bumpers or light grids. This allows you to match the HOLZ-HER machining centers individually and reliably to your operating situation.

Always included – the CAMPUS control with integrated CabinetControl Base software. Our high quality, user-friendly HOLZ-HER machine control system is an integral part of the machine’s design. The equipment package includes CAMPUS / NC Hops with office and machine license and full-fledged aCADemy CAD software. The integrated CabinetControl Base furniture design software rounds out this premium package.

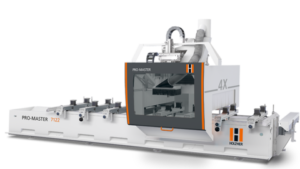

HOLZ-HER PRO-MASTER 7018 premium: The All Round Talent with Complete Equipment PackageVector Speed 100 m/min= 4,000″/min.

With the CNC machining center PRO-MASTER 7018 premium, HOLZ-HER provides the perfect solution for state-of-the-art, rational CNC machining for modern production shops. Standard features include four axes – all fully interpolating for maximum flexibility.

With the CNC machining center PRO-MASTER 7018 premium, HOLZ-HER provides the perfect solution for state-of-the-art, rational CNC machining for modern production shops. Standard features include four axes – all fully interpolating for maximum flexibility.

The PRO-MASTER 7018 premium is distinguished by its fully new industrial design. State-of-the-art encapsulation of the machining head offers many advantages such as a good view of the machining field when moving in workpieces. The extreme machining dimensions up to 5,220 mm x 1,285 mm and solid design make this machine predestined for pendular processing on doors and construction elements. (Click Picture for 7018 Video)

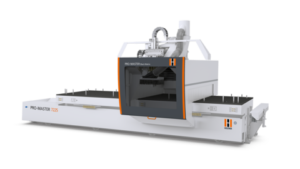

CNC machines PRO-MASTER 71 series: unlimited possibilities in the field of plastics and woodworking:

ProMaster 7122 CNC machining center for woodworking, you also have to decide on the right choice of drive – 4-axis or 5-axis technology.Here, HOLZ-HER covers all drive options with the CNC machines of the 71er PRO-MASTER series. The two “sisters” PRO-MASTER 7122 and PRO-MASTER 7125 are characterized by their extremely stable design and state-of-the-art control and drive technology. The basic equipment of the 71er series is already full-fledged and extensively equipped, so that the decision ultimately comes to the right number of controlled axles.

Both the PRO-MASTER 7122 4-axis machine and the PRO-MASTER 7125 5-axis machine have an enormous processing capacity with a true processing height of 210 mm (8″) from the upper edge of the vacuum suction device. (Click Picture for 7125 Video)

CNC machines PRO-MASTER 72 series: Master extreme machining dimensions in wood machining with confidence, Vector Speed 142 m/min= 5,600″/min.

Step up to the next generation of CNC machining with the 72 PRO-MASTER series from HOLZ-HER. The 72 series CNC machining centers are distinguished particularly by their extreme machining dimensions and perfect cutting results as well as high material removal rates. Generous machining dimensions for the console table with up to 7,200 mm in the X direction and 1,600 mm in the Y direction as well as a Z stroke of 565 mm provide for highly variable, custom machining on the 72 series CNC machines.

Step up to the next generation of CNC machining with the 72 PRO-MASTER series from HOLZ-HER. The 72 series CNC machining centers are distinguished particularly by their extreme machining dimensions and perfect cutting results as well as high material removal rates. Generous machining dimensions for the console table with up to 7,200 mm in the X direction and 1,600 mm in the Y direction as well as a Z stroke of 565 mm provide for highly variable, custom machining on the 72 series CNC machines.

The 72 series is completed by a versatile and comprehensive range of optional equipment to satisfy all desires, allowing each CNC machining center to be configured optimally for applications in the fields of furniture production, staircase construction and model making as well as machining solid wood.

The 4-axis PRO-MASTER 7222 and the 5-axis PRO-MASTER 7225 have an enormous machining capacity with effective machining height of 300 mm 12″ – from the top of the suction cups.

The 4-axis PRO-MASTER 7222 and the 5-axis PRO-MASTER 7225 have an enormous machining capacity with effective machining height of 300 mm 12″ – from the top of the suction cups.

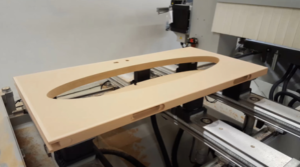

5 Axis Application video: Click on picture for video:

Software- CAMPUS – the high quality, user-friendly machine control from HOLZ-HER

The HOLZ-HER machine control system is an integral part of the machine’s design. The equipment package includes our comprehensive CAMPUS/NC Hops software. This package provides the prerequisites for effective machining and convenient operation. Our ECO Mode automatic standby control is a standard feature on all HOLZ-HER CNC machining centers for software-controlled minimization of the power consumption.

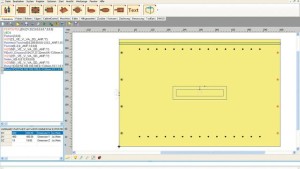

Campus aCADemy is a full fledged, high-performance CAD/CAM software package with versatile import features.

In addition to variable programming, 3D views and simulations, the NC Hops editor offers full Z axis interpolation and a text editor.

»Easy Snaps«, adjustable parameters and well-conceived macros additionally simplify and speed up program control.

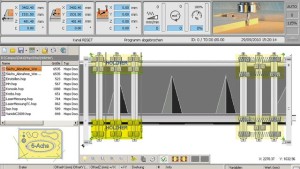

The work center shows the occupancy of the machine table. Tools, drilling heads and paths are automatically optimized for all workpieces and the machining times are calculated.

The tool manager MT Manager allows clear, graphic set-up using »Drag & Drop«.

Including sequence simulation.

Open software architecture allows simple incorporation of existing data and connection to a wide range of branch, design and CAD/CAM softwares.

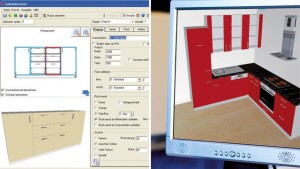

CabinetControl – software for simple furniture designing

Our high quality, user-friendly HOLZ-HER machine control system is an integral part of the machine’s design. The equipment package includes CAMPUS

NC Hops with office and machine license and full-fledged aCADemy CAD software. The integrated CabinetControl Base furniture design software rounds out this premium package. This offer provides the prerequisites for effective machining and convenient operation with barcode interface, manual control unit, import features and much more.

CabinetControl Base included as standard feature in software package.

Design of furniture.

Views can be represented in 2D or 3D.

Quick adaptation to individual desires of furniture buyers.

Perfect presentation of furniture.

Automatic completion of cutting plans.

Generates CNC machining program automatically at the touch of a button.

An optional professional version, the CabinetControl PRO, is also available with library, calculation, data transfer to pressure beam saws, etc.

Also ideal for planning kitchens and rooms.

Call Maze LLC today at 214-418-7572