HOLZHER BEAM SAWS

HOLZ-HER LINEA 6015: From craftsmen for craftsmen

Some call this special equipment. We call it standard.

The HOLZ-HER LINEA 6015 pressure beam saw sets new standards in the economy class. Most powerful saw motors in their class, rapid setup times for prescoring saw and gentle, scratch-free panel handling. Numerous refinements in software and hardware will also convince you of the advantages of the LINEA 6015. To ensure the perfect quality of your cutting work, the LINEA 6015 provides everything as standard features, such as air cushions on the support and machine table or the prescoring unit with 2.2 kW of power.

The HOLZ-HER LINEA 6015 pressure beam saw sets new standards in the economy class. Most powerful saw motors in their class, rapid setup times for prescoring saw and gentle, scratch-free panel handling. Numerous refinements in software and hardware will also convince you of the advantages of the LINEA 6015. To ensure the perfect quality of your cutting work, the LINEA 6015 provides everything as standard features, such as air cushions on the support and machine table or the prescoring unit with 2.2 kW of power.

The high acceleration values and cutting away from the stop fence are your guarantee for fastest cycle times and maximum process reliability.

Detailed information here: https://www.holzherusa.com/us/products/beam-saws/linea-6015.html

Video: https://vimeo.com/holzher

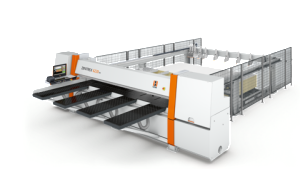

HOLZ-HER ZENTREX 6220 lift: The Space-Saving Lift Solution, Including Lifting Table

The ZENTREX 6220 lift from HOLZ-HER is the complete solution with solid elevating table for high throughput mass production. The low space requirement and enormously high supporting capacity of the ZENTREX 6220 lift allow high speed processing at high material throughput rates using package cuts. This elevating table version from HOLZ-HER thus ensures optimum integration into existing production processes. Four Versions, Classic, Power, Dynamic and Lift.

The ZENTREX 6220 lift from HOLZ-HER is the complete solution with solid elevating table for high throughput mass production. The low space requirement and enormously high supporting capacity of the ZENTREX 6220 lift allow high speed processing at high material throughput rates using package cuts. This elevating table version from HOLZ-HER thus ensures optimum integration into existing production processes. Four Versions, Classic, Power, Dynamic and Lift.

All HOLZ-HER pressure beam saws in the ZENTREX 6220 series set new standards in the upper class with enormous dynamic power and use of precision technology such as ground linear guides and controlled servo-drives with CNC technology. All moving axes are equipped with precision, brushless servo-drives for optimum performance. The completely redesigned PLC control offers minimum cycle times in addition to extreme accuracy. Further Details Here:

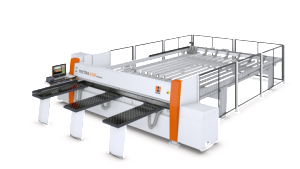

HOLZ-HER TECTRA Series: The Adaptable Pressure Beam Saws with the High Performance Spectrum

In times of highly specific customer requirements and low production quantities, custom solutions are required to achieve the synergistic effects of horizontal pressure beam saws combined with intelligent charging equipment. As with the TECTRA 6120 lift, charging is possible using an integrated lifting table system or on the TECTRA 6120 power, direct charging to the machine from a horizontal storage facility. For maximum performance requirements, the TECTRA 6120 dynamic model allows the pressure beam saw to be charged with new panels from storage even while the previous cutting operation is still in progress, without interrupting the current sawing cycle. Four Versions Classic, Power, Lift and Dynamic.

In times of highly specific customer requirements and low production quantities, custom solutions are required to achieve the synergistic effects of horizontal pressure beam saws combined with intelligent charging equipment. As with the TECTRA 6120 lift, charging is possible using an integrated lifting table system or on the TECTRA 6120 power, direct charging to the machine from a horizontal storage facility. For maximum performance requirements, the TECTRA 6120 dynamic model allows the pressure beam saw to be charged with new panels from storage even while the previous cutting operation is still in progress, without interrupting the current sawing cycle. Four Versions Classic, Power, Lift and Dynamic.

Thanks to its high acceleration values and feed rates, the TECTRA 6120 can process even large quantities of panels rationally. This versatile saw is available with various cutting lengths and cutting widths, allowing it to be adapted to highly varying applications as a custom solution. Further Details here:

The high performance software package for large HOLZ-HER TECTRA beam saws

The control is decisive for the power output of a state-of-the-art pressure beam saw. The TECTRA series is controlled by our CUTCONTROL 2 and the preinstalled EASY-PLAN and OPTI-CUT software packages.

Everything at a glance:

Standard, large 19″ monitor (with optional touchscreen) and large, clearly arranged buttons make it possible to machine absolute, series and format cuts with integrated groove.

OPTI-CUT and EASY-PLAN optimization software preinstalled at the factory.

Individual jobs can be assigned a priority at any time, job programming parallel to cutting.

Graphic 3D user interface for intuitive operation and machine sequence functions for NC cutting.

Program-controlled measurement of reference dimensions when saw blade is changed.

Information display indicating running meters for main and prescoring saws.

Individual adaptation of function and parameter settings.

Label printer (optional) for barcode labels.

(also data matrix barcode incl. software module for creating labels.