FRIULMAC End Coping/Tenoning Solutions

Tradition, innovation, flexibility and quality.

The wood-working machinery manufacturing industry has been an Italian tradition for over 50 years. Friulmac with its fifty years is a perfect example of a growth that this sector has experienced over in Italy, placing the country itself on the top of the world-wide machinery exporters list. Friulmac main facilities are located in the North-Eastern part of Italy near the city of Udine. 10.000 sq m manufacturing plant.Friulmac’s product range includes heavy duty double and single end tenoners, standard as well as custom built working centre for furniture, entry door and cabinet door components, handling equipment, feeding systems and hopper feeders for moulders.

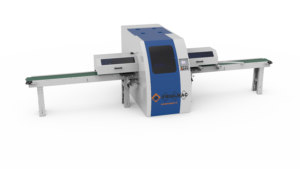

RANDOMT E

Our best seller: the compact and versatile solution for the end

Our best seller: the compact and versatile solution for the end matching of parquet elements and cabinet door components. With a moderate investment, RANDOMAT-E allows the continuous feeding of random length work-pieces and the processing of any kind of profile. 10-14 cycles per minute.

matching of parquet elements and cabinet door components. With a moderate investment, RANDOMAT-E allows the continuous feeding of random length work-pieces and the processing of any kind of profile. 10-14 cycles per minute.

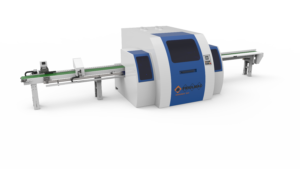

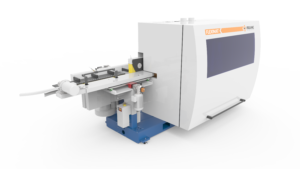

RANDOMAX EVO

RANDOMAX EVO represents the best solution of its category. A solid and versatile machine that allows the trimming and profiling of solid wood or plywood flooring elements with fix or random length. Possibility to equip the machine with cutting, profiling, upper and lower scoring units. Along With Defecting within the machine for reduction in operating cosy. Up to 60 ft/min

RANDOMAX EVO represents the best solution of its category. A solid and versatile machine that allows the trimming and profiling of solid wood or plywood flooring elements with fix or random length. Possibility to equip the machine with cutting, profiling, upper and lower scoring units. Along With Defecting within the machine for reduction in operating cosy. Up to 60 ft/min

CONTOURMAT

CONTOURAMAT: easy to use, compact and extreme productive! One of Friulmac’s ever best seller. Only one operator required. End-Cope any kind of profile. The compact design reduces the space requirements. Extra short changeover time for different profiles. Guarantees precision and high profiling quality with no tear-out. Can be assembled with end- boring, vertical and edge boring units.

45° bevel cutting (vertical axe). 12-18 parts/minutes

Fleximat

The FLEXIMAT series has been designed to cope with a wide variety of products in the field of fixtures, furniture and panel processing, ranking at the top of the category for sturdiness and reliability. Equipped with work-piece return systems or integrated in automatic processing lines, it represents the most flexible solution for both small or large production requirements.