WEINIG UNIMAT MOULDERS

Unimat 217/218 (Over 15,000 Units sold in North America)

A Standardized Moulder With Outstanding Features And Attractive Options

A Standardized Moulder With Outstanding Features And Attractive Options

5 or 6 spindle configurations.

6000 RPM spindle speed.

Up to 25 HP motors for the largest profiles.

Feed speed up to 90 ft. per minute.

Chromed table plates standard for abrasive timber or MDF.

Central lubrication points for easy maintenance.

Receding chipbreakers, pneumatic feed roller pressure and driven table rollers are standard equipment. Installation and Training provided by Factory Trained Weinig Engineer.

Unimat 317/318-The work horse

The powerful series with an impressive list of standard features and options for just about any type of production. All at a very attractive price! If you know of the older series of U22A, Unimat 23EL, Unimat 1000 and others, the Unimat 300 series is here for you.

Available in configurations ranging from the basic 5 spindles up to 2 right spindles, 2 top spindles and a Universal head for 360 degree profiling. The choice is yours. 6000 RPM spindle speed. Motor choices up to 50 HP! PowerCom touch screen is standard along with some automatic spindle positioning.

Many options available for very short stock, straightening, sawing, equalizing and other components not available from any other manufacturer.

Many options available for very short stock, straightening, sawing, equalizing and other components not available from any other manufacturer.

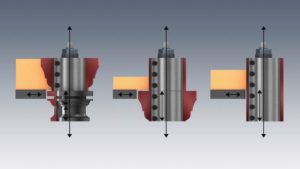

With a tool cutting circle of 225mm (8 7/8″) on the bottom spindle, multiple parts are possible up to a height of 55mm (2.160″). You can choose to have up to a 50 HP motor on the bottom spindle for the heavy power demands of sawing.

Inserts for the table plates and pressure shoe are available for sawing from the top or bottom, or both.

Sawing single pieces into multiple parts requires the addition of anti-kickback fingers for operator safety.

Unimat 618-The Millwork Moulder

A definite step up in capacity from the other machines in the Unimat line, the Unimat 618 is made for bigger profiles and heavier production.

Larger spindles and larger cutting circles are just a part of what makes the Unimat 618 the “workhorse” of the Unimat line. Large standard and available motor sizes coupled with 8000 RPM spindle speeds instantly adds 33% to your production rates! PowerCom touch screen is standard along with some automatic spindle positioning.

Many configurations are possible, as well as options for very short stock, straightening, sawing, equalizing and other components not available from any other manufacturer.

100% Weinig quality at a surprisingly low price!

Some of the technical specifications of the Unimat 618 :

Width capacity: 9 1/16″ wide.

Extra height capacity as standard – 6 1/4″ thick.

8000 RPM spindle speed for extra feed speed without specialized tooling.

Spindle diameter: 1 13/16″ for heavy profiling without outboard bearings.

Extended axial movement of spindles – 80mm (3 1/8″) on vertical spindles, 45mm (1.770″) on horizontal spindles for stacked profiles and full width use of planing heads. More efficiency with less tooling cost.

Large cutting circles for deep profiles.

Up to 50 HP motors available for horizontal spindles.

Spindle brakes and safety hood standard on all models.

Unimat 818 (12″ wide)

The affordable way to make a high quality moldings! Weinig engineering has responded to market demand for a 12″ width capacity machine at an unprecedented price!

Modular construction using pre-built elements lets us offer you a heavy-duty 12″ wide moulder with outboard bearings and lots of horsepower for wide production like stair treads and profiled fascia. But also designed to run small profiles with the ease of setup you expect from Weinig..

Many options available for very short stock, straightening, sawing, equalizing and other components not available from any other manufacturer. PowerCom touch screen is standard along with some automatic spindle positioning.

Some of the technical specs of the Unimat 818 :

Width and height capacity: 12 1/16″ wide – 6 1/4″ thick.

6000 RPM spindle speed.

Spindle diameter: 1 13/16″ with axially-adjustable outboard bearings.

Extended axial movement of spindles – 80mm (3 1/8″) on vertical spindles, 45mm (1.770″) on horizontal spindles for stacked profiles and full width use of planing heads. More efficiency with less tooling cost.

Large cutting circles for deep profiles.

Up to 50 HP motors available for horizontal spindles.

Spindle brakes and safety hood standard on all models.

In the new Unimat 818, Weinig brings its customers the perfect combination of optimum surface quality and large profile capacity from a reliable source.

Quality, reliability, flexibility and price – all from a company trusted for generations.

Unimat Series More in Depth Here!