HolzHer Nesting with The Dynestic Series

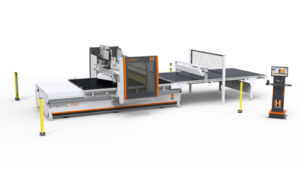

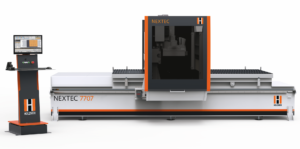

The Nesting CNC machine DYNESTIC 7505 enables highly efficient panel processing with the latest nesting technology in modern gantry design. With machining dimensions of 5′ x 10′ & 5′ x 12′, the optimized design allows the shortest machining cycles with the best machining results.

The Nesting CNC machine DYNESTIC 7505 enables highly efficient panel processing with the latest nesting technology in modern gantry design. With machining dimensions of 5′ x 10′ & 5′ x 12′, the optimized design allows the shortest machining cycles with the best machining results.

The Nesting CNC Machining Center is equipped with an integrated 6-fold linear tool changer, which can be optionally extended to up to 12 changing stations. The new highlight of this machine is an LED machine label with indication of the operating state: depending on the color of the lettering you see immediately in which operating state your machine is. In addition, the DYNESTIC 7505 has high-performance spindles with ceramic bearings as well as a fully-equipped drill head with up to 24 drilling spindles and slot saws in the X direction.

Detailed Video Here (Just Click or picture above)

Click on picture for Video of operation:

Dynestic Overview Nesting with Pods Labeling

On Board software Laser alignment Cabinet nesting assemble methods

Eco-Flow Table and Vacuum Pumps

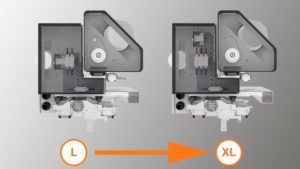

Additional Features and Options

Materials:

Nesting 7532 for packaging companies: Click Picture for video:

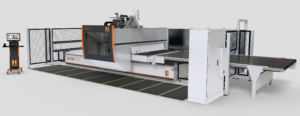

The Nesting machine DYNESTIC 7505 is available in the classic variant as well as in the push variant with an automatic push-button and integrated suction as well as with a removal table including conveyor belt.

Perfectly tailored for your applications. Select the single machine classic or the push variant.

Classic variant (1) The classic variant without automation components.

Push variant (2) The push variant pushes the finished nest onto the conveyor belt and cleans the machine table for the next processing.

Push variant (2) The push variant pushes the finished nest onto the conveyor belt and cleans the machine table for the next processing.

Lift variant (3) The Lift variant loads & pushes the finished nest onto the nest table and pushes the finished nest onto the conveyor belt and cleans the machine table for the next processing.

MAZE LLC today: 214-418-7572 or email [email protected] for more info.